As usual when New Year approaches I'm looking back at the year's progress on my model of Nystrup Gravel. 2020 has been quite a different year due to the corona virus with its huge implications to most countries around the world. In Nystrup the cosy little rural 600 mm gravel line in 1/19 scale hasn't suffered much, although a lot of work has been dimishing available time for modelling.

2020 began with at start on a new loco project - a Danish built diesel engined locomotive from Pedershaab. I got the bare plasticcard frames motorized and running on battery power and then the project stalled. In December I dusted my drawings off and got started again. I have sent measurements, sketches and images to a manufacturer that have helped me with projects before. The plan is to have axle boxes and springs 3D-printed. I also had new electronic gadgets delivered to help remote control the locomotive.

Finding track supplies and designing my model track took some time in the beginning of 2020. In the process I got sidetracked by experiments with wooden track. My work with track planning has progressed so far that I am finally ready to build the first track in 2021. Sleepers has been cut and stained, rail and spikes bought, track gauges made and a small section of cork track bed glued in place.

In June I got to the point where I began actually building my small layout. The small L-shaped layout will be my interpretation of part of the gravel handling and sorting facility in Nystrup. In 16 mm scale there isn't room for a lot, so careful selection of scenes is definately needed. Framework and basic surface features are almost ready. 2021 will begin with finishing the basic landscape and preparing it for track building. I look forward to try landscape and track building in 1/19. I am a beginner in this scale and I proceed carefully to not rush anything. I hope not to make too many mistakes.

A new 4 wheeled coach set wheels on the Nystrup rails. The coach was modelled on the basis of a real Nystrup Gravel prototype - as yet undocumented and based on anecdotal evidence only. The theory of a 4 wheeled coach at Nystrup Gravel is however, well founded on archive research involving postcards sent by the gravel company manager Holm. My model is from a sligthly rebuilt and detailed kit from The Line Side Hut and primarily built during my summer holiday.

|

| Test running the new coach. Nystrup loco no. 3 carefully pushing coach no. 3 along the line. A worker has been posted as a lookout on the front platform. |

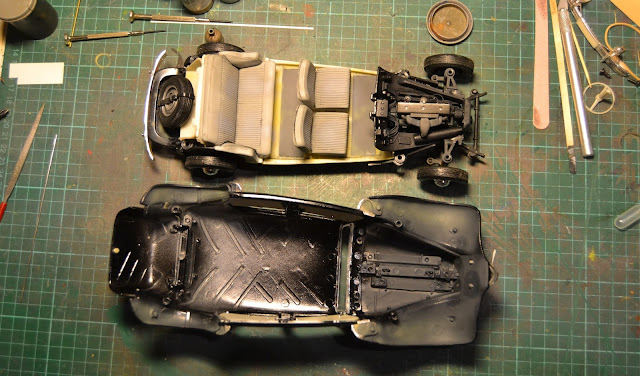

Several road vehicles arrived in my collection during 2020, but only a Citroen Traction Avant and a Ferguson TEA-20 tractor were detailed and weathered to enable them to be displayed on my future layout. Decals for the newly aquired vehicles were designed and have arrived from my decal supplier, assuring me that 2021 can include the usual work on non-railway vehicles.

|

| The Ferguson was the tractor which kick started the mechanization of Danish farming. Here my version of the Schucho 1/18 scale model with added details and weathering. |

During spring and early summer I painted six DIN skips in different coatings of dark greys and weathering. Some of them got a rather harsh treatment with both hammer and a heavy layer of rust. I used Vallejo chipping fluid for the first time with mixed result, while I liked using a hammer to physically weather the skips. In April I even used a combination of beer and rock music to assist the weathering process. Surely a sensible way to chase away the frustrations of corona lock-down and working from home.

|

| Three newly painted skips in the spring sunshine. |

My research of Nystrup Gravel's history continued, despite corona restrictions making visits to archives difficult. Several images from the company's industrial railway was found, and a series of old post cards sent by the company's manging director also surfaced, quickly leading to building of a 4 wheeled coach. Currently I have resumed contact with the granddaughter of Thorleif Petersen, the Nystrup Gravel workshop manager for many years. I hope that will provide new insight into the history of Nystrup Gravel.

|

| Despite the corona pandemic HVB kept the trains running, although with reduced capacity. Here a train with dieselelectric M 25 from 1959 meets a train pulled by Da 7 from 1921. |

|

| Pre-corona railway fun with mates. No distancing, masks or travel restrictions, but smiles all around! Besucherbergwerk 'Voller Rose' near Ilmenau, autumn 2019. |

For the Nystrup Gravel blog 2020 was a pretty active year with a steady stream of posts averaging 4 posts pr month. The statistics says visits to the blog are in the range of 2.500-3.000 page views pr month as they have been for several years. There has been a slight decline in visitors during the last three months. Perhaps because I haven't described a 'real' railway project since I finished the coach in September? As the blog is a reflection of my modelling, not the other way round, there isn't a great deal I'm going to do about it. I don't choose modelling projects to have something interesting to write about on the blog. And after all, modelling a Danish narrow gauge industrial railway in 1/19 scale isn't exactly mainstream railway modelling.

I hope you enjoyed some of the stories from Nystrup Gravel during the year or had the chance to catch up in this review of 2020. I wish you a happy New Year and hope to see you again in 2021 for more modelling, fictional history and prototype information.