Recently a reader of the blog asked how my workbench is arranged. Quite small and very simple is the short answer. In a recent issue of the internet magazine

'Model Railroad Hobbyist' one modeller took the readers for a impressive sightseeing through his perfectly laid out modelling workshop. Imagine, he had a whole room just for building models! The layout was housed in an other, much larger room.

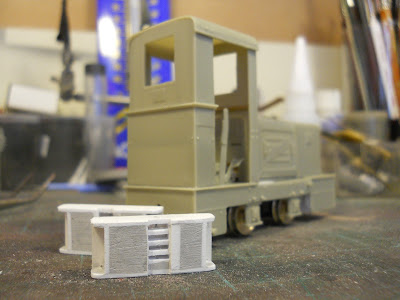

My modelling is done on an area no larger than 100 x 150 cm. The image below was taken by leaning well back in my chair. So if anyone expected my workbench to be huge, well it isn't.

|

| Cleaned up workbench. Building of the Roadcraft Bedford O-tipper in progress. To the left is a small vice (made in the USSR), a mini drill and airbrush (both German). To the right is two cardboard tubes with wood and metal profiles, an assortment of primer and clear varnish in spray cans. Brushes, glues, decal solutions and old film canisters used for mixing paint can be seen as well. |

The worktable is actually built into one of the well known IKEA shelf modules called Ivar. As such I sit halfway into my storage of built and unbuilt models. Under the table I keep all my tools in a small plastic tool box next to my near-silent Italian air compressor. In the shelf to the left is a small stock of sheet plastic and profiles as well as prototype info on the models currently being built. The magnetic strip over the table is used for instructions during the building. On the wall behind me is my ever growing collection of books on industrial railways, railways in general, old lorries, construction equipment as well as the result of my own 'research' into Danish industrial railways. The 'cave' is accessed by squeezing past the house's 'stationary' laptop mostly used by me (all other computers and mobile devices in the house are very much mobile - but nevertheless always out of my reach!) and the small rolling cabinet that holds my paints and all parts 'electrical' - wires, switches etc.

|

| Frontpage of the Danish Hobby Magazine, October 1967 showing a pipe enthusiast's workshop arranged in a closet. Looks cosy and notice the enthusiast is wearing shirt and tie while working! While my work area isn't that small, it shows that with imagination you can always find room for your hobby. |

If nothing else I hope to prove, that modelling can be done even in very limited space - and that lack of room isn't a good excuse for not building models. Running trains may be difficult with limited space, but building trains can be done in a small closet.