It's time again for the annual review from the little railway at Nystrup Gravel. As previous years I've complained in several posts over too little time for modelling and too little progress on my tiny layout. But when I give it a little more thought here at the year's end, I realize I would be hard pressed to devote more time for it. I have a real daytime job (sometimes even stretching beyond daytime hours), a family and I volunteer on a vintage railway that takes priority over my 'toy train' at home.

|

A train of empty skips rolling gently down the ramp. Comparing with images after the rails have been painted I think it is obvious how much rail painting improves the overall impression of a model railway.

|

Despite all my complaining about too little time for modelling I managed to have the track on the small layout almost finished by year's end. Only the track on the loading ramp is still unfinished as the work with landscaping and vegetation has to be carried out before I'm confident that I can finish the ramp without hindering work under it. Traffic and shunting on the layout is now possible and can be conducted without reduced speed other than those that are prototypically implied by the nature of a primitive narrow gauge industrial railway. It's been fun building track in 1/19 scale and when mixing track building with other tasks I have escaped the frustration of routine that have overwhelmed many railway modellers building their own track. My layout is very small and track lengths limited which have surely helped too. No matter how short the tracks are, my homebuilt track counts as the most significant achievement in 2021.

|

Home built track with the first layer of rust paint added. I'm really glad I chose to build my own track rather than rely on out-of-the-box PECO SM32-track.

|

|

Building track in 1:1 scale takes more effort and help from good mates than track building in 1/19 scale. Full scale track building makes you much more fit than model building, though! Photo: KHA.

|

There is a lot of positive mutual spill-over effects between my full scale volunteering and Nystrup Gravel. Building full scale track makes me much more aware of what to replicate in miniature. While it's only natural that most inspiration flows from the 'real' world to my model railway, sometimes Nystrup Gravel shows up in the real world too.

|

A married couple celebrated their 25. wedding anniversary with a train ride on HVB and a professional photograper's memorial photo of them and their daughters. An old original wooden box from Nystrup Gravel is serving in the scene. Photo: Per Dyrby.

|

Landscaping the Nystrup Gravel layout (I really hesitate calling the areas next to the track on my layout 'landscape' as it's such a diminutive area) gradually progressed during 2021 and basic ground cover was provided by disposable kitchen rags soaked in white glue with a layer of earth coloured paint. It's extremely basic, but avoids the layout looking too unfinished until I get to grips with ballasting and more comprehensive ground detailing. As a start I managed to place a few stones used as infill at the loading ramp sticking out of the ground. The stones are bedded into the ground and surrounded by gravel spillings from the ramp above and the beginning of coarse vegetation. My Christmas gift for myself was an RTS Grassmaster 55 kV stratic grass applicator that I look forward to employ on grassing duties in the coming months.

|

The complete Nystrup Gravel layout being given some fresh air in the garden. In June almost the entire surface was covered by kitchen rags and light brown paint.

|

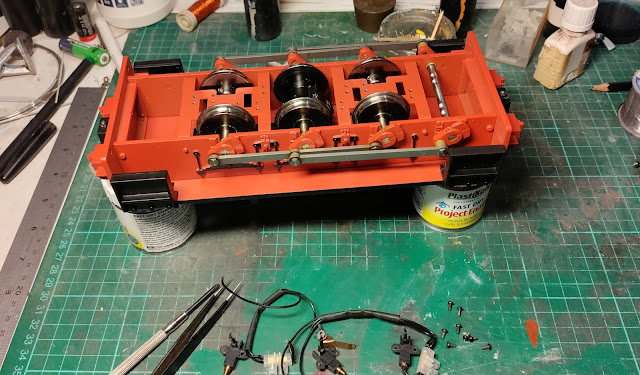

There is a pressing need for more traction power at Nystrup Gravel and reinforcements are coming. 2 locos are on my own workbench and one is being built abroad. All 3 projects seems to be suffering from hesistant builders, global supply chain difficulties combined with covid-19 side effects. It is perfectly clear though, that something has to happen on the traction front in 2022 - the Lister cannot continue being the only locomotive on Nystrup Gravel. While my Pedershaab-model has been test run nothing has really happened on it in 2021, except for the design and delivery af 3D-printed axle boxes. On the large Baguley-Drewry I removed the current collecting parts and test ran the loco on the layout powered by a 9 V battery. It worked quite well and the loco navigated all track on the layout without problems. Perhaps I will simply be using a rechargable 9 V battery to power the loco?

|

The Baguley-Drewry on its way down the ramp. A challenging curve for such a large loco.

|

Quite unusual only one car entered service in the Nystrup universe during the year. A Best of Show Volvo Duett showed up with Danish license plates and slight weathering in May. While not yet detailed and weathered for service a Series 1 Land Rover also joined the collection of 1950's cars. I managed to buy a comparatively cheap example of the detailed Minichamps model on Ebay. It will most likely be fitted with markings from the local state forrest commission.

|

The Volvo Duett and another new arrival: the figure of Nystrup Gravel's chief mechanic Thorleif Petersen with green enamel cup in hand.

|

2 new figures came to Nystrup Gravel in 2021. One of them is a figure of the legendary Nystrup Gravel chief mechanic Thorleif Petersen. The other is a so far unknown nameless worker carrying an oil can finished after I was tested positive for covid-19 on the 24. December. The test sent me into selfisolation for the following 7 days according to the Danish authorities' rules. As I have not had any symptoms at all, it has so far been a relatively cozy experience. Being isolated in my hobby room/railway library and served delicious food and drinks sounds good, doesn't it? What's even better is that I have not infected the rest of the family. Until now I have enjoyed painting 2 figures and I hope to get to do even more modelling while in isolation.

|

Worker with oil can outside the fuel and lubrication shed. Despite being only a temporary solution the painted kitchen rags give a nicely grainy surface texture.

|

Regarding the blog statistics I must confess that I didn't study them too closely in 2021. When I, here at year's end take a look at the numbers, it's pretty much the same picture as the last few years. The blog has in average obtained 2-3.000 page views a month and some 35.000 page views in total for 2021. The most viewed post in 2021 was the 'New Locomotive'-post about my new Baguley-Drewry locomotive from March with a little over 300 views. After my change from 1/35

scale to 1/19 in 2018/2019 there is still no 1/19 scale post in top 10

of the blog's all time views. The many years of 1/35 scale modelling keep 'haunting'

the blog and the old top posts with 8-6.000 views are difficult to

challenge as they still attract quite alot of traffic from interested readers around the planet. And speaking of the planet, the predominant part of the blog's readers are living outside of my homeland Denmark. This year Danish readers have been frequently visiting Nystrup Gravel bringing Denmark to a 3 place on the list of visitors ranked by country/state with Sweden and USA coming in on 1 and 2 place. Close in the heels of Danish readers are enthusiasts from the United Kingdom and Germany with Australians and New Zealanders next in the race.

|

The blog's readers have been able to follow my experiments with track building, ballasting and vegetation in the track.

|

Let me finish the review of 2021 with the best wishes for every reader's 2022. I'll keep reporting from the little large scale layout and the more or less steady progress of the line. Happy New Year!