With the end of the year 2016 only a few hours away it's time to sum up the modelling fun I've had. Once again quite a lot has been going on. The year started with the arrival of a 1:35 scale Fowler from Australia. Designed, built and painted by Chris Millar the locomotive have had a few test runs and I also managed to build a driver figure for the loco. Lots of tasks remaining, though. The loco was one of my few purchases for Nystrup Gravel during 2016. I made a decision to try and clear away some of the kits and projects already sitting on my shelves.

A nice summer made it possible for me to spend a lot of time on the porch. I have found that most modelling tasks can be done outside. A result of the modelling done there was an almost finished new module showing the gravel line passing by the factory complex of Banke's Bakelite. For several years the little stream running under the 600 mm. tracks of Nystrup Gravel have been completely dry. In 2016 I finally pulled myself together to get the water done. I had heard a lot of modellers having trouble with the commercially available water products. I simply chose to paint gloss varnish on the stream's gravel bed. I built up several layers and liked the effect.

Anyone having read more than five blog posts here will know that I enjoy making road vehicles. During 2016 I finished a tractor for my trailer from the small building contractor 'Solvang Entreprenørforretning'. A bus also made it's debut on the roads around Nystrup. On both bus and trailer tractor I managed to get good masked and air brushed paint schemes. It seems that my painting practice finally paid off.

The year's last finished models were two Hudson bogie flat wagons. I had worked on them on and off during the last three years and finally made my mind up to finish them. Modelling is a hobby but sometimes it takes a little extraordinary determination to finish a project. Having the discipline to finish every model is an important part of my modelling - it helps me maintain focus and not start too many projects.

I hope to continue modelling the gravel company's little railway and parts of the environment around the line in 2017. Happy New Year!

Saturday 31 December 2016

Sunday 25 December 2016

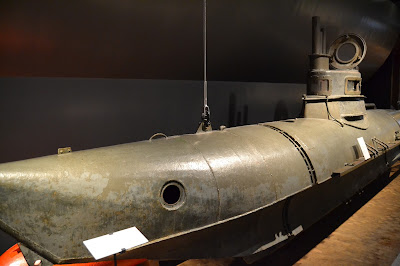

Sub Scrap (1/35)

A few weeks ago a friend of mine suggested I build a Billing Boat wooden kit of a small Danish fishing boat in 1:30 scale. I thought the project a bit too large for my Nystrup setting. The idea of some kind of a ship had caught my mind, though. No place in Denmark is more than 50 km. from the sea and despite Nystrup not being directly at the coast line, I began to wonder how something like a miniature boat could be squeezed in near Nystrup.

The smallest 1:35 boat I was able to find was a German miniature submarine of the type Biber (Beaver). Luckily the Biber was one of three types of miniature submarines (Molch, Neger and Biber) found on the German airfield not far

from Nystrup. Most of them were taken away for scrap in 1946-47 after evaluations by the British. In this way the presence of a rusty sub on a lorry around Nystrup wouldn't be completely out of the question.

The kit is from Italeri and quite easy to assemble although I put in some time getting rid of a seam along the top of the hull. As submarines really isn't what turns me on modelling wise I kept my own modifications to a minimum. I opend up a few of the bolted covers in the sides of the boat. To conduct technical examinations I suppose the British technicians removed them for easier access.

.

On my visit to the Berlin Technical Museum I had the opportunity to see a real Biber. Apart from its small size I was struck by the fact that the rudders were made from wood. As a weapon the Biber wasn't a success. Most were lost at sea because of mechanical failures, rough sea or because their 'drivers' died from carbon monoxide poisoning due to a badly designed exhaust system.

The kit is from Italeri and quite easy to assemble although I put in some time getting rid of a seam along the top of the hull. As submarines really isn't what turns me on modelling wise I kept my own modifications to a minimum. I opend up a few of the bolted covers in the sides of the boat. To conduct technical examinations I suppose the British technicians removed them for easier access.

.

|

| The two main hull parts ready for assembly. |

|

| The Biber assembled and ready for primer. Posed on a track panel the boat will most likely end up as a load on a lorry. |

On my visit to the Berlin Technical Museum I had the opportunity to see a real Biber. Apart from its small size I was struck by the fact that the rudders were made from wood. As a weapon the Biber wasn't a success. Most were lost at sea because of mechanical failures, rough sea or because their 'drivers' died from carbon monoxide poisoning due to a badly designed exhaust system.

|

| The Biber in the Berlin Technical Museum. Not much of a submarine at barely over six tons. |

|

| Also the Biber in Berlin is missing a cover. Notice the somewhat buckled surface of the boat. |

Thursday 22 December 2016

Modelling and Consistency (1/35)

Now that's a weird headline. But to me it's pretty straight forward, really. To be believable a model railway has to make a balanced and good impression. To me that means that all the elements of the model railway fit together. Period and theme seems to be major considerations for many railway modellers. It is for me too. I also try to get the same level of detail on trains, buildings, figures and road vehicles. To make everything blend together. Exactly like in reality, where a lorry isn't any less detailed than a locomotive.

I have participated in the Danish Gauge 1 exhibitions since the event was first held in 2010 and I have seen my share of bare plywood layouts with expensive locos and rolling stock. The contrast is striking and unrealistic. Nevertheless this years event showed how the Gauge 1 scene in Denmark is fast developing. From the huge collections of mostly German rolling stock and locos in 'out of the box-condition' running on naked plywood ovals. To kit and scratch built rolling stock with realistic weathering running on landscaped modules set up to feature end to end running. Nystrup Gravel didn't participate in this year's version of the event. Due to a tight schedule and career priorities I decided to skip the event. I hope to return to the event next time and enjoy even more Gauge 1 modelling!

|

| A section of track on the Nystrup Gravel line. My attempt at making track as detailed as everything else I build or use. |

I have participated in the Danish Gauge 1 exhibitions since the event was first held in 2010 and I have seen my share of bare plywood layouts with expensive locos and rolling stock. The contrast is striking and unrealistic. Nevertheless this years event showed how the Gauge 1 scene in Denmark is fast developing. From the huge collections of mostly German rolling stock and locos in 'out of the box-condition' running on naked plywood ovals. To kit and scratch built rolling stock with realistic weathering running on landscaped modules set up to feature end to end running. Nystrup Gravel didn't participate in this year's version of the event. Due to a tight schedule and career priorities I decided to skip the event. I hope to return to the event next time and enjoy even more Gauge 1 modelling!

Tuesday 13 December 2016

Nystrup Gravel's Wagons no. 49 and 51 (1/35)

It may have taken some time, but now the two Hudson bogie wagons are ready for service on the 1:35 scale version of Nystrup Gravel. I started building the wagons from two David Prowan kits back in September 2013. Now more than three years later the wagons are evidence that I finish what I start - also when modelling.

Nystrup Gravel used the two wagons to transport bagged sand for foundry use. Nystrup's foundry sand 'Multisand' was a specialised product sold to foundries in both Denmark and Germany. The two wagons were bought from Great Britain through the Danish dealer of narrow gauge equipment V. Spøer. The wagons were delivered with steel sides which were obviously discarded quite soon by the Danish workers as they hampered easy on- and offloading. At least one of the steel drop doors was left rusting behind the loco shed for many years. In the recent issue (108) of Narrow Gauge & Industrial Railway Modelling Review the Hudson bogie wagons are mentioned as having been delivered in large numbers to the British War Office for use in e.g. ammunition dumps.

When the second wagon was painted I could add the final weathering to both

of them. I used pastel chalk for dust on the load area and graphite from a soft pencil for worn metal - primarily on the buffers on the bogies. I painted 19 sacks and added decals - enough for a symbolic

load on one wagon. The next 25-30 sacks will be done when I need a therapeutic break from another project.

Being from etched metal and fitted with white metal bogies the wagons are comparatively heavy for their size. I fitted the bogies with a thin washer between bogie and wagon and small gap between the two to enable the bogies to adjust to uneven track. Time will show if more weight and washers are needed for safe running.

Nystrup Gravel used the two wagons to transport bagged sand for foundry use. Nystrup's foundry sand 'Multisand' was a specialised product sold to foundries in both Denmark and Germany. The two wagons were bought from Great Britain through the Danish dealer of narrow gauge equipment V. Spøer. The wagons were delivered with steel sides which were obviously discarded quite soon by the Danish workers as they hampered easy on- and offloading. At least one of the steel drop doors was left rusting behind the loco shed for many years. In the recent issue (108) of Narrow Gauge & Industrial Railway Modelling Review the Hudson bogie wagons are mentioned as having been delivered in large numbers to the British War Office for use in e.g. ammunition dumps.

|

| The two Hudson wagons (one unloaded) photographed in front of 'Bankes Bakelit'. Apparently the original Hudson bogies were swapped for rebuilt skip frames at Nystrup. |

Being from etched metal and fitted with white metal bogies the wagons are comparatively heavy for their size. I fitted the bogies with a thin washer between bogie and wagon and small gap between the two to enable the bogies to adjust to uneven track. Time will show if more weight and washers are needed for safe running.

|

| Jung loco no. 6 shunting wagons 49 and 51 between the small industries in the western part of Nystrup. |

Friday 9 December 2016

Approaching the Finish Line - Bogie Wagons (1/35)

With a troubled history my two Hudson bogie wagons are now approaching the finish line. Being put back in a card board box several times due to missing parts or lack of motivation the wagons are now subject to a focused building and painting process. Fueled by the delivery of decals for the load of sacks and last week's progress on one of the wagons.

With new found energy I glued on the 68 rivets (made from thinly sliced strched sprue) on the remaining wagon and primed it and its two bogies. A few of the cleaned up resin sacks were quickly painted and prepared for decals. When paint and varnish had dried I fitted the decals designed for the sacks. As expected the decals fitted perfectly on the resin sacks from Wespe Models.

Next time you'll hear about the two bogie wagons they will be completely finished. I promise. You won't hear more about them for some time after that. I have a few other projects to tell you about in the time to come.

|

| Cleaned up resin sacks and fresh decals from 'Skilteskoven'. The sacks will hopefully make the otherwise quite dull wagons a little more interesting. |

|

| One newly primed flat wagon and its almost finished cousin carrying a few test samples of sacks with foundry sand. |

Next time you'll hear about the two bogie wagons they will be completely finished. I promise. You won't hear more about them for some time after that. I have a few other projects to tell you about in the time to come.

Subscribe to:

Posts (Atom)