2023 is fast approaching its end and I'm enjoying a cup of coffee in a comfy reading chair in my library/workshop. I'm looking back on the year's events for the 1/19 scale Nystrup Gravel layout. Definately not a year without progress, but the number of posts has never been lower. With only 34 posts 2023 even underperformed the 'annus horribilis' of 2017 that reached 35 posts. On the other hand the blog could celebrate post number 500 in August with a story about new grass tufts from Spain.

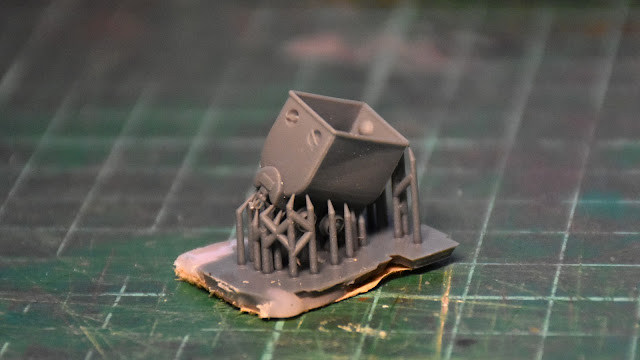

The year began with work on three of the six 3D printed Hudson underground skips that Nystrup Gravel used for ash and general spoil transport to empty parts of the old gravel pits. The finishing of the three narrow profile underground skips was somewhat delayed as I squashed and broke a finger while building a 1/1 scale platform. That meant a break from modelling, but not more than I could visit a large Danish model railway exhibition.

The most visible progress on the layout has been my continued work with landscaping and vegetation. In april I managed to build the stairs used by the workers to access the loading ramp and finish the ground cover on the ramp module with a mix of used ground coffee, sieved gravel, small stones and twigs. Most of it was soon covered by static grass in several colours. The plank road and gravel covered area at the ramp was also almost finished, now lacking only the final detailing. In the final weeks of 2023 I began working my way through module 1 with ground cover and coarse sisal grass.

|

| The area around the loading ramp was covered in grass of several lengths, colours and coarseness during 2023. |

The most monumental leap forward for Nystrup Gravel was however the beginning of installation of battery and remote control equipment in the Fowler diesel. A project that had been postponed for far too long due to difficulties in acquiring RC-equipment from a supplier. After a long proces I lost patience and bought WiFi-equipment from Loco Remote - no waiting needed for their services! Within 14 days I had two Loco Remote Maxi units on my door step. That even included customs processing and payment as Loco Remote is located in the United Kingdom and Nystrup Gravel in the Kingdom of Denmark, European Union. Expect news about the Fowler in the near future.

The first stages in the rebuild of the Fowler was succesfully completed in 2023. The huge battery pack was removed and a new cab floor assembly was built. For a more reliable service with the Nystrup Gravel skips I also lowered the buffers on the loco.

|

| Lowered buffers on the Fowler to fit the layout's fleet of skips. Looking at the photo I'm glad I chose to build the track myself. It looks much more prototypically than standard Peco SM32 track. |

2023 was a year where, for the first time in many years, no new road vehicles were added to the collection. The Land Rover Series I bought in 2021 received the usual treatment of decals fitting the Nystrup setting; Danish license plates, detail painting and a light weathering. As a vehicle from the Danish National Forest District 4 the Land Rover is now an active part of the car collection. My work on the Land Rover even prompted a good Danish modelling colleague to work on his Land Rover as well. Check his work on the Sundborg blog out here - in Danish, but with lots of images.

|

| The Minichamps Land Rover parked in the wrong side of the road. Both passenger and driver has left the vehicle. Perhaps to study rare flowers in the ditch? |

During 2023 I began a series of small scale experiments. Of course it is a distraction from my main modelling effort, but small scale modelling is fun and a different challenge. It also allows me to explore an Eastern European theme that I have always wanted to try. In march some 3D printed kits arrived from Kyiv and occasional work on them saw a PD-1 draisine on a small diorama finish in November. I hope to take the Eastern European H0e adventure a bit further and have bought track and some mining equipment to slowly start a small scene.

|

| With the fields and forest near Baranyvka in the background draisine no. 2 of type PD-1 poses on its small diorama. |

During the year I have been trainspotting abroad on a few occasions. Mostly in neighbouring Sweden where I went both in my professional capacity for a Danish railway contracting company and for fun with a team of mates from my vintage railway. The 31. Internationales Feldbahntreffen in Germany was also paid a visit. Two German societies had teamed up for the event and consequently I checked in at both Frankfurter Feldbahnmuseum and Feld- und Grubenbahnmuseum Fortuna. Some great days was spent enjoying narrow gauge and networking with enthusiasts preserving our industrial heritage. In 2024 the 32. Internationales Feldbahntreffen will be hosted by the Hedeland vintage railway in Denmark.

During 2023 I got all the blog posts with content in 1/35 scale clearly marked with the appropriate scale in the title. That should help readers distinguish between my previous 1/35 scale and current 1/19 scale. With my main focus on modelling in 1/19 scale it is interesting that the most popular 1/19 scale post of the year is only the fourth most viewed post on the blog. Two posts about 1/35 modelling and one with 1/87 lead the race for most popular post of the year in 2023. It shows that years of modelling Nystrup Gravel in 1/35 scale still appeals to modellers out there and the blog is still searched for.

|

| Top 5 of the most viewed posts on the Nystrup Gravel blog in 2023. |

The number of views is slowly increasing and passed 56.000 views in 2023. I hope visitors take something with them from their visits no matter what scale they model in. I visit several blogs in different scales that inspire and provide me with new methods.

Next year I hope to cover the layout completely with vegetation. I have shopped some artificial plants that I will test for providing different textures to my layout. I also hope to finally getting the Fowler running and detailed to my usual standard. Lights and wooden poles with power cables are also on the schedule for 2024 as well as detailing a pair of road vehicles. Perhaps I can even begin working on the Baguley-Drewry?

Happy New Year to readers wherever you may be located. I wish you health and fortune, particularly if you've had a less than happy 2023.

.JPG)

%202.JPG)