With the end of the year 2016 only a few hours away it's time to sum up the modelling fun I've had. Once again quite a lot has been going on. The year started with the arrival of a 1:35 scale Fowler from Australia. Designed, built and painted by Chris Millar the locomotive have had a few test runs and I also managed to build a driver figure for the loco. Lots of tasks remaining, though. The loco was one of my few purchases for Nystrup Gravel during 2016. I made a decision to try and clear away some of the kits and projects already sitting on my shelves.

A nice summer made it possible for me to spend a lot of time on the porch. I have found that most modelling tasks can be done outside. A result of the modelling done there was an almost finished new module showing the gravel line passing by the factory complex of Banke's Bakelite. For several years the little stream running under the 600 mm. tracks of Nystrup Gravel have been completely dry. In 2016 I finally pulled myself together to get the water done. I had heard a lot of modellers having trouble with the commercially available water products. I simply chose to paint gloss varnish on the stream's gravel bed. I built up several layers and liked the effect.

Anyone having read more than five blog posts here will know that I enjoy making road vehicles. During 2016 I finished a tractor for my trailer from the small building contractor 'Solvang Entreprenørforretning'. A bus also made it's debut on the roads around Nystrup. On both bus and trailer tractor I managed to get good masked and air brushed paint schemes. It seems that my painting practice finally paid off.

The year's last finished models were two Hudson bogie flat wagons. I had worked on them on and off during the last three years and finally made my mind up to finish them. Modelling is a hobby but sometimes it takes a little extraordinary determination to finish a project. Having the discipline to finish every model is an important part of my modelling - it helps me maintain focus and not start too many projects.

I hope to continue modelling the gravel company's little railway and parts of the environment around the line in 2017. Happy New Year!

Saturday, 31 December 2016

Sunday, 25 December 2016

Sub Scrap (1/35)

A few weeks ago a friend of mine suggested I build a Billing Boat wooden kit of a small Danish fishing boat in 1:30 scale. I thought the project a bit too large for my Nystrup setting. The idea of some kind of a ship had caught my mind, though. No place in Denmark is more than 50 km. from the sea and despite Nystrup not being directly at the coast line, I began to wonder how something like a miniature boat could be squeezed in near Nystrup.

The smallest 1:35 boat I was able to find was a German miniature submarine of the type Biber (Beaver). Luckily the Biber was one of three types of miniature submarines (Molch, Neger and Biber) found on the German airfield not far

from Nystrup. Most of them were taken away for scrap in 1946-47 after evaluations by the British. In this way the presence of a rusty sub on a lorry around Nystrup wouldn't be completely out of the question.

The kit is from Italeri and quite easy to assemble although I put in some time getting rid of a seam along the top of the hull. As submarines really isn't what turns me on modelling wise I kept my own modifications to a minimum. I opend up a few of the bolted covers in the sides of the boat. To conduct technical examinations I suppose the British technicians removed them for easier access.

.

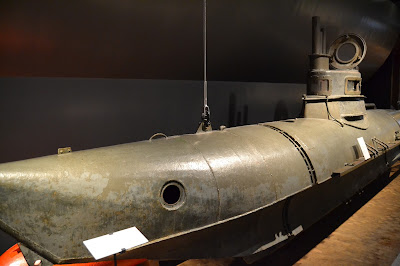

On my visit to the Berlin Technical Museum I had the opportunity to see a real Biber. Apart from its small size I was struck by the fact that the rudders were made from wood. As a weapon the Biber wasn't a success. Most were lost at sea because of mechanical failures, rough sea or because their 'drivers' died from carbon monoxide poisoning due to a badly designed exhaust system.

The kit is from Italeri and quite easy to assemble although I put in some time getting rid of a seam along the top of the hull. As submarines really isn't what turns me on modelling wise I kept my own modifications to a minimum. I opend up a few of the bolted covers in the sides of the boat. To conduct technical examinations I suppose the British technicians removed them for easier access.

.

|

| The two main hull parts ready for assembly. |

|

| The Biber assembled and ready for primer. Posed on a track panel the boat will most likely end up as a load on a lorry. |

On my visit to the Berlin Technical Museum I had the opportunity to see a real Biber. Apart from its small size I was struck by the fact that the rudders were made from wood. As a weapon the Biber wasn't a success. Most were lost at sea because of mechanical failures, rough sea or because their 'drivers' died from carbon monoxide poisoning due to a badly designed exhaust system.

|

| The Biber in the Berlin Technical Museum. Not much of a submarine at barely over six tons. |

|

| Also the Biber in Berlin is missing a cover. Notice the somewhat buckled surface of the boat. |

Thursday, 22 December 2016

Modelling and Consistency (1/35)

Now that's a weird headline. But to me it's pretty straight forward, really. To be believable a model railway has to make a balanced and good impression. To me that means that all the elements of the model railway fit together. Period and theme seems to be major considerations for many railway modellers. It is for me too. I also try to get the same level of detail on trains, buildings, figures and road vehicles. To make everything blend together. Exactly like in reality, where a lorry isn't any less detailed than a locomotive.

I have participated in the Danish Gauge 1 exhibitions since the event was first held in 2010 and I have seen my share of bare plywood layouts with expensive locos and rolling stock. The contrast is striking and unrealistic. Nevertheless this years event showed how the Gauge 1 scene in Denmark is fast developing. From the huge collections of mostly German rolling stock and locos in 'out of the box-condition' running on naked plywood ovals. To kit and scratch built rolling stock with realistic weathering running on landscaped modules set up to feature end to end running. Nystrup Gravel didn't participate in this year's version of the event. Due to a tight schedule and career priorities I decided to skip the event. I hope to return to the event next time and enjoy even more Gauge 1 modelling!

|

| A section of track on the Nystrup Gravel line. My attempt at making track as detailed as everything else I build or use. |

I have participated in the Danish Gauge 1 exhibitions since the event was first held in 2010 and I have seen my share of bare plywood layouts with expensive locos and rolling stock. The contrast is striking and unrealistic. Nevertheless this years event showed how the Gauge 1 scene in Denmark is fast developing. From the huge collections of mostly German rolling stock and locos in 'out of the box-condition' running on naked plywood ovals. To kit and scratch built rolling stock with realistic weathering running on landscaped modules set up to feature end to end running. Nystrup Gravel didn't participate in this year's version of the event. Due to a tight schedule and career priorities I decided to skip the event. I hope to return to the event next time and enjoy even more Gauge 1 modelling!

Tuesday, 13 December 2016

Nystrup Gravel's Wagons no. 49 and 51 (1/35)

It may have taken some time, but now the two Hudson bogie wagons are ready for service on the 1:35 scale version of Nystrup Gravel. I started building the wagons from two David Prowan kits back in September 2013. Now more than three years later the wagons are evidence that I finish what I start - also when modelling.

Nystrup Gravel used the two wagons to transport bagged sand for foundry use. Nystrup's foundry sand 'Multisand' was a specialised product sold to foundries in both Denmark and Germany. The two wagons were bought from Great Britain through the Danish dealer of narrow gauge equipment V. Spøer. The wagons were delivered with steel sides which were obviously discarded quite soon by the Danish workers as they hampered easy on- and offloading. At least one of the steel drop doors was left rusting behind the loco shed for many years. In the recent issue (108) of Narrow Gauge & Industrial Railway Modelling Review the Hudson bogie wagons are mentioned as having been delivered in large numbers to the British War Office for use in e.g. ammunition dumps.

When the second wagon was painted I could add the final weathering to both

of them. I used pastel chalk for dust on the load area and graphite from a soft pencil for worn metal - primarily on the buffers on the bogies. I painted 19 sacks and added decals - enough for a symbolic

load on one wagon. The next 25-30 sacks will be done when I need a therapeutic break from another project.

Being from etched metal and fitted with white metal bogies the wagons are comparatively heavy for their size. I fitted the bogies with a thin washer between bogie and wagon and small gap between the two to enable the bogies to adjust to uneven track. Time will show if more weight and washers are needed for safe running.

Nystrup Gravel used the two wagons to transport bagged sand for foundry use. Nystrup's foundry sand 'Multisand' was a specialised product sold to foundries in both Denmark and Germany. The two wagons were bought from Great Britain through the Danish dealer of narrow gauge equipment V. Spøer. The wagons were delivered with steel sides which were obviously discarded quite soon by the Danish workers as they hampered easy on- and offloading. At least one of the steel drop doors was left rusting behind the loco shed for many years. In the recent issue (108) of Narrow Gauge & Industrial Railway Modelling Review the Hudson bogie wagons are mentioned as having been delivered in large numbers to the British War Office for use in e.g. ammunition dumps.

|

| The two Hudson wagons (one unloaded) photographed in front of 'Bankes Bakelit'. Apparently the original Hudson bogies were swapped for rebuilt skip frames at Nystrup. |

Being from etched metal and fitted with white metal bogies the wagons are comparatively heavy for their size. I fitted the bogies with a thin washer between bogie and wagon and small gap between the two to enable the bogies to adjust to uneven track. Time will show if more weight and washers are needed for safe running.

|

| Jung loco no. 6 shunting wagons 49 and 51 between the small industries in the western part of Nystrup. |

Friday, 9 December 2016

Approaching the Finish Line - Bogie Wagons (1/35)

With a troubled history my two Hudson bogie wagons are now approaching the finish line. Being put back in a card board box several times due to missing parts or lack of motivation the wagons are now subject to a focused building and painting process. Fueled by the delivery of decals for the load of sacks and last week's progress on one of the wagons.

With new found energy I glued on the 68 rivets (made from thinly sliced strched sprue) on the remaining wagon and primed it and its two bogies. A few of the cleaned up resin sacks were quickly painted and prepared for decals. When paint and varnish had dried I fitted the decals designed for the sacks. As expected the decals fitted perfectly on the resin sacks from Wespe Models.

Next time you'll hear about the two bogie wagons they will be completely finished. I promise. You won't hear more about them for some time after that. I have a few other projects to tell you about in the time to come.

|

| Cleaned up resin sacks and fresh decals from 'Skilteskoven'. The sacks will hopefully make the otherwise quite dull wagons a little more interesting. |

|

| One newly primed flat wagon and its almost finished cousin carrying a few test samples of sacks with foundry sand. |

Next time you'll hear about the two bogie wagons they will be completely finished. I promise. You won't hear more about them for some time after that. I have a few other projects to tell you about in the time to come.

Tuesday, 29 November 2016

Flat Wagon Progress (1/35)

With soldering done the two wagons were washed thoroughly with hot water and a used toothbrush. When the wagons were dry I began fitting plastic details like brackets and rivets. The work adding rivets is somewhat tedious. Consequently my motivation hasn't been sky high.

| |

| One of the wagons with boards test fitted as low sides and sacks with foundry sand. The drawing is my concept for a decal for the sacks. I'm slowly cleaning up the many sacks - one more boring task! |

|

| Finally I pulled myself together and finished rivetting one of the wagons. It and the bogies got primed immediatly and now awaits painting. |

Thursday, 17 November 2016

A Local Hobby Shop in Berlin

While in Berlin this summer I came across this fantastic shop front of a hobby shop. Apart from childrens' toys the shop carried a lot of plastic kits, railway books and a wide selection of Märklin model railway items inside. But most amazing to me was the old fashioned shop front with neon signs in old Märklin design. If you fancy a visit yourself, find the shop on Wilmersdorfer Strasse 157 in Charlottenburg, Berlin or visit the shop's website.

|

| The iconic neon signs over the shop front windows. Must look wonderful when lit in the dark. |

Thursday, 10 November 2016

A Long Story: Hudson Bogie Wagons (1/35)

Almost three years ago I started building two bogie flats in an attempt to recreate the two wagons used by Nystrup Gravel to carry foundry sand in sacks. The build process was stalled by several factors and the wagons somehow ended up in a box. The wagons have now returned to my work bench again and I'm determined to get them finished this time.

Status on the wagons is that all soldering is done and my home made bogies test fitted with cut down M2 bolts. As the kit's etched end angle profiles where too short I replaced them with pieces of brass profile cut and filed to suit.

I'm now progressing with cleaning up my solder work which wasn't up to my usual standard. Next is fitting of small details like rivets. The load will need some work too, as the sand bag resin castings aren't exactly perfect.

|

| The box has landed. I can begin to plan what has to be done, how and in what sequence. |

Status on the wagons is that all soldering is done and my home made bogies test fitted with cut down M2 bolts. As the kit's etched end angle profiles where too short I replaced them with pieces of brass profile cut and filed to suit.

|

| The end profiles are filed to the right length in my small vice. |

|

| I got the vice as a birthday present in my early teens from my mom and dad. In more than one way a piece of history now. The Union of Socialist Soviet Republics was dissolved in December 1991 |

|

| Both wagons ready for clean up. I bought the resin sand bags from Wespe Models on a Summer sale when I had another kit sent north anyway. |

Monday, 31 October 2016

Bus ready for departure (1/35)

My 1:35 scale version of the Opel bus from the Nystrup-Ubehage-Dimholt-Skovby route is now ready for departure. The route connected the towns of Nystrup and Skovby via a route through the dark and inhospitable woods around the small hamlets Ubehage and Dimholt.

In the last blog post on the bus I was getting ready to fit sides to the model. An operation I had read other modellers found rather difficult. Thanks to that knowledge I was well prepared and the actual process went smoother than expected.

With the sides fitted I finished the weathering of the interior and prepared the seats for instalment. The seats are placed extremely close to each other and there is very limited room for the model figures to be fitted as passengers later. Perhaps the bus was the inspiration for the design of the seat placing in Ryan Air commercial airliners?

I applied the decals with the use of decal softener and setter from Mr. Hobby. While I don't really know if the setter liquid does anything useful, the softener definately helps the decals to conform the model's surface. When satisfied with the decals I gave the bus a final layer of gloss varnish.

After fitting two passengers, a driver and fitting the windows I closed up the bus by gluing the roof in place (see the figures built and painted in this previous post). Originally I had planned to fit more passengers, but the seat spacing makes it difficult. Other modellers planning to build the bus could perhaps consider adjusting the spacing by leaving out a row of seats? On the roof rack I placed the spare wheel, a fuel canister and a suitcase tied down with EZ Line.

With the bus finally finished I can now move on to other tasks. More on those projects coming up soon.

|

| The bus picking up a passenger on its way to Nystrup. |

|

| Sides fitted to the chassis. The roof is only temporarily fitted. |

|

| Ready for fitting of the seats. |

|

| The bus during detail painting. After painting I gave the complete model a layer of gloss varnish to prepare the surface for the decals. |

After fitting two passengers, a driver and fitting the windows I closed up the bus by gluing the roof in place (see the figures built and painted in this previous post). Originally I had planned to fit more passengers, but the seat spacing makes it difficult. Other modellers planning to build the bus could perhaps consider adjusting the spacing by leaving out a row of seats? On the roof rack I placed the spare wheel, a fuel canister and a suitcase tied down with EZ Line.

|

| Crossing the viaduct over Nystrup Gravel's 600 mm. line. The bus is heading north towards Ubehage on its way to Skovby. |

|

| A rear view of the Opel Blitz bus. Made from a 1:35 scale kit from Ukrainian manufacturer Roden. |

Tuesday, 11 October 2016

Fowler Driver Finished (1/35)

Last blog post left the Fowler driver ready for primer and paint. In this post the driver will be painted, weathered (yes, I apply weathering to figures too) and placed in the Fowler's cab.

Working on figures can be a modelling adventure in itself. I try to have a relaxed attitude toward figure modelling and have no ambitions of reaching anything near the military modellers' accomplishments that are stunning. My model figures are there to help locomotives and vehicles appear realistic and give a hint of size. I set off 1-2 effective hours of work for modelling and painting each figure. In my opinion that is a good compromise between the horrific prefinished figures you can buy for Gauge 1 (1:32 scale) model railways and the masterpieces from military modellers.

|

| I mentioned that I built the Fowler driver while making figures for my Opel bus. Here they are all four of them before primer. |

|

| Two figures with primer. To avoid fumes from the primer I bring items for priming outside the house. |

|

| Main colours have been brushed on the figures. I have used Vallejo acrylics. The paints don't smell, they flow well from my brushes and are easily cleaned from the brushes with tap water. |

|

| Loco driver in position in the cab. |

Sunday, 2 October 2016

Fowler Driver (1/35)

As I was in the proces of constructing three figures for my Opel bus, I took the opportunity to build a driver figure for my Fowler diesel. The figure is the first stage in a series of tasks I will perform on the Fowler in the months to come.

Even though 1:35 scale is supplied with a good selection of figures useful for a model railway like mine, there is no escape from scratch building if I want to add a realistic driver to my model locomotives. The following images show how I built a driver for the Fowler loco. I used parts from four figures from the MiniArt set 35009 'Soviet Tank Crew at Rest' combined and suitably modified.

Even though 1:35 scale is supplied with a good selection of figures useful for a model railway like mine, there is no escape from scratch building if I want to add a realistic driver to my model locomotives. The following images show how I built a driver for the Fowler loco. I used parts from four figures from the MiniArt set 35009 'Soviet Tank Crew at Rest' combined and suitably modified.

|

| Legs from two figures modified and combined to fit the Fowler's floor. |

|

| Before the glue fully dried, I placed the leg assembly on the foot plate to check for a good fit. |

|

| With Miliput I built up the coverall on the leg fitted with a high boot. I tested two different upper bodies for the most natural stance of the driver. |

|

| Upper body and head fitted. A little unusual for a 1950's Danish worker are the steely look a'la 'Hero Soviet Worker' and no cloth cap. I decided to live with that. |

Sunday, 25 September 2016

The Bright City Lights (1/35)

Well, some may argue that I'm taking this post's head line a bit to far! Nystrup isn't a city and the lights are merely some dim lamps in a few industrial buildings. No matter what I like the atmosphere they create. I hope to develop the modules further in that direction to underline the difference between the dark woods around the gravel pits and the lights of Nystrup town.

While there is probably a way more advanced for controlling lights in buildings, I'm still attracted to the simple mechanical method of using toggle switches. I've wired the lights in the factory building through some small plugs. That enables me to still 'pull out' the interior of the building despite the considerable number of wires for the lighting.

|

| It's after dark now and the lights are out on the first floor of Banke's Bakelite. Still plenty of other lights in the small industrial district in Nystrup. |

While there is probably a way more advanced for controlling lights in buildings, I'm still attracted to the simple mechanical method of using toggle switches. I've wired the lights in the factory building through some small plugs. That enables me to still 'pull out' the interior of the building despite the considerable number of wires for the lighting.

|

| Cut out in the module's front for the recessed panel holding the switches for light in the factory building and the grounded goods van. Looks a mess in this photograph! |

Wednesday, 14 September 2016

Back to the Work Bench (1/35)

After a week long break I'm now going back to modelling. I have been quite busy with paper work for the heritage railway you probably know I'm involved with. To be allowed to operate, any heritage railway in Denmark will have to meet certain standards and document their safety procedures. It's a lot of paper work even for a small narrow gauge railway. With most of the work done I should now be able to do a little modelling again.

|

| Here is the small decal sheet for my blue and orange 1:35 Opel bus. Produced by 'Skilteskoven' in Odense for a modest sum of money. Can't wait to fit them to my model! |

Thursday, 1 September 2016

Optimizing Loco Running (1/35)

As I have my modules set up for operation it is only natural to work on some of my locos' running qualities. While my two Billards with BullAnt drive units are perfect, slow runners I still have some trouble with loco 78 also fitted with a BullAnt. I'm cleaning wheels, adjusting pick ups, checking for clearances to the loco body and adding a little more weight. Until 78 runs as smooth as the Billards and is fit to star in a run past film clip, here are two photos from one of the test runs.

Sunday, 28 August 2016

Main Building at Banke's Bakelite Finished (1/35)

After a long construction period the contractor (me) has finally finished work on the main building at the 1:35 scale bakelite factory in Nystrup. Not because it's been difficult or boring, but because I work on several models simultanously.

While waiting for decals for my Opel Blitz bus, I took the opportunity to work on the factory. The main parts of the model are laser cut from MDF and card board by a friend of mine. Interior and roof was cut from foam board in 4 and 6 mm. thickness. Some of the work has been the subject of an earlier blog post.

Previously I had fitted light to the ground floor rooms and I did the same to the single first floor room. I then painted the interior walls on the first floor light grey and made a removable floor. That allows me access to the ground floor lights if they should need any attention in the future.

I built the roof from two sandwiched layers of foam board covered with self adhesive surgical tape. The tape is my preferred method of modelling tar paper. The tape is slightly 'furry' and when painted retains a nicely textured surface.

After having painted the building I cut a rear wall to enable the model to be closed up and hold the removable interior in place. The rear wall is only kept in place by its tight fit and is easily removed to allow the interior to slide out of the building. Wires from the lights are run under the module surface inside the building. The wires are arranged to allow the lights to be switched on and off in all three rooms independently.

|

| The main building at Banke's Bakelite is now finished. My next task is to glue it solidly to the module and blend it into the surrounding ground work. |

Previously I had fitted light to the ground floor rooms and I did the same to the single first floor room. I then painted the interior walls on the first floor light grey and made a removable floor. That allows me access to the ground floor lights if they should need any attention in the future.

|

| Installing light above the first floor in the factory building. |

I built the roof from two sandwiched layers of foam board covered with self adhesive surgical tape. The tape is my preferred method of modelling tar paper. The tape is slightly 'furry' and when painted retains a nicely textured surface.

|

| Foam board roof with wooden edging fitted to the building. |

|

| Surgical tape covering the roof. Pencil marks helped me to position the strips of tape with a minimum of regularity. |

After having painted the building I cut a rear wall to enable the model to be closed up and hold the removable interior in place. The rear wall is only kept in place by its tight fit and is easily removed to allow the interior to slide out of the building. Wires from the lights are run under the module surface inside the building. The wires are arranged to allow the lights to be switched on and off in all three rooms independently.

|

| A view across Nystrup Gravel's track towards Banke's Bakelite. Now work on getting the building fit into the surrounding ground work can begin |

Subscribe to:

Comments (Atom)