With Christmas and New Year celebrated and having settled stage 1 of the work associated with my daughter's wedding and new apartement, I finally got half an hour at the hobby table. The result was a rolling 3D printed Hudson underground skip, one of six that arrived shortly before Christmas. A lot of work still remain, but as a 'proof of concept' the result was satisfying enough.

.JPG) |

| U-tub skip for underground use next to a standard Hudson V-skip. |

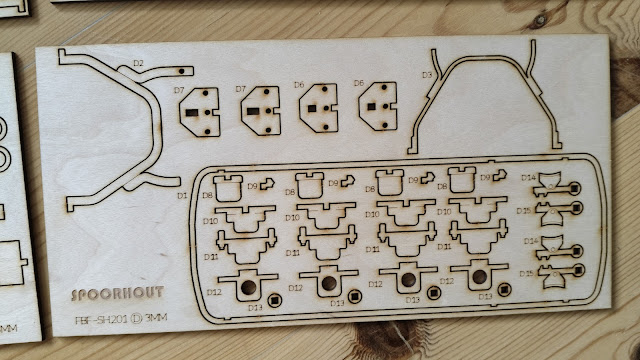

With a 3D printed construction a small model like the Hudson skip is extremely light - even in a scale as large as 16 mm. With some rather coarsely printed wheels thrown under the construction I expected a model with less than mediocre running qualities. To enhance running replacement metal wheels would be a natural solution, but as I haven't yet found any metal wheels of the correct type I'm going to use the printed ones for a start. That means that I have to cram as much weight into the skip as possible, preferably as low as possible to avoid a high centre of gravity.

First I had to get the skip running. The wheels are designed for 3 mm axles and I ordered axles as well as brass tube with a 3 mm internal diameter to fabricate bearings. When arriving the brass tube turned out to be 5 mm outer diameter and impossible to fit in the model's axleboxes without wrecking them. It turned out that Albion Alloys had thin-walled brass tube with a 4 mm outer diameter. The tubes were even available from a Danish seller, SMT- modeltog, making a delivery to my door in less than 48 hours possible. To make the postage worth the investment, I added some glues to my order.

|

| BT4M brass tube with 4 mm outer diameter and inner diameter of 3,1 mm. |

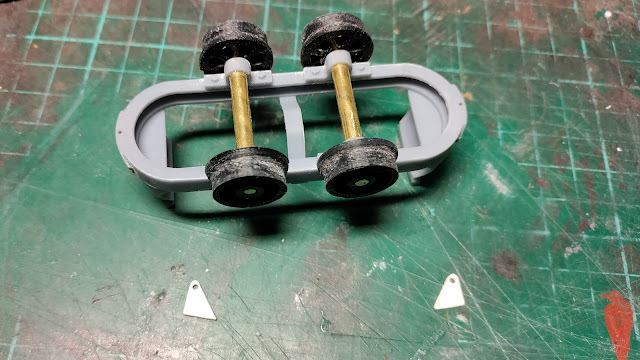

Picking a skip frame, I quickly sanded most of the printing traces from the sides of the frame and opened up the holes in the axleboxes to 4 mm. To make the wagon a few grams heavier, I decided to cut a single, long brass bearing completely enveloping the 3 mm brass axle instead of two bearings fitted into the axleboxes on each side of the skip. With limited view of anything below the skip's tub I think the slightly larger appearance of the axle will hardly be noticed. The axles were cut to length (39 mm even if the instructions said 42 mm). The wheels' axleholes were reamed with a 3 mm drill, the axle fitted in the tube bearings and the wheels pushed on. Before fitting, the wheels were cleaned up a bit and the worst dimples on the running surfaces removed. The wheels are by no way worse than what I have seen on prototype industrial narrow gauge rolling stock in Denmark. In model they may need further treatment, though.

.JPG) |

| Tube bearings, axles and wheels fitted. The wheel profile isn't the prettiest I've seen! |

.JPG) |

| Skip frame on my Code 100 test track undergoing the first rolling test. |

The first finger pushing tests conducted on a test track and the on the real Nystrup Gravel track, showed that he wagon behaved quite well, even on uneven and curved track. Next up is adding a little weight in the tub and making tests with loco pushing. Once the rolling tests and weight experiments have been carried out I will take the skip apart again and figure out how to fit coupling chains and hooks. Then it will need sanding and add ing of texture, painting and weathering. And then there is five more waiting! I have previously done

assembly line work on identical models and I will probably do the same on the underground skips.

.JPG) |

| All parts for a single skip brought together on my worktable test track panel. |

.JPG) |

| After being hand pushed on the layout with reasonably succes the U-tub skip is now resting, waiting for further tests and improvements. |

.JPG)

.JPG)

.jpg)

y.jpg)

.JPG)

y.jpg)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)