As usual I bring a project for some slow vacation modelling in the cottage. This year I chose three 3D printed Hudson underground skips. They are second stage of a six wagon build proces with three skips finished in first stage back in 2023. With experience from building the first three skips there shouldn't be much to worry about!

|

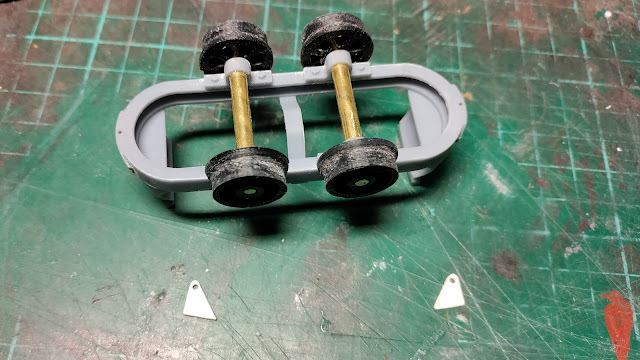

| Three skips posing assembly line like on the cottage table cloth. One-piece full length 4 mm diameter brass bearings fitted. |

|

| One skip fitted with wheels - two still waiting. |

The skips' wheels are designed for 3 mm axles and I used Albion Alloys thin-walled brass tube with a 4 mm outer diameter for bearings. To make the wagon a few grams heavier, I cut a single, long brass bearing completely enveloping the axle instead of two bearings fitted into the axleboxes on each side of the skip. With limited view of anything below the skip's tub the slightly larger appearance of the axle has hardly been noticable on the first three wagons. The axles were then cut to length and the wheels' axleholes were reamed with a 3 mm drill, the axle fitted in the tube bearings and the wheels pushed on.

Before fitting, the wheels were cleaned up a bit and the worst dimples on the running surfaces removed with a sanding stick.

|

| Three skips fitted with 'caked on' ash on frames and skip bodies. The modeller enjoying a beer while working. |

|

| The putty has dried and now lead sheet is fitted as ballast. |

Before the wheels were fitted, I sanded the printing traces from the sides of the frames. That was an easier job than to remove the traces on the sides of the skips' tubs. As the wagons were used to transport ash on Nystrup Gravel I'm applying a heavy weathering that will help to cover the last traces of the printing proces. From prototype photos the skips were covered with 'cakes' of ash on the sides and to represent that, I added texture to the skips with modelling putty. I applied the putty with a wooden toothpick and worked the semi-dried putty into a thin layer with texture with an old tooth brush.

With the putty dried I turned my attention to fit the lead ballast that is crucial to achieve accetable running from the skips. The first pieces of lead sheet was super glued into the skip body rests after being bent to a perfect fit.

Now work to bend up couplings are waiting.

.JPG)

.JPG)

.jpg)

y.jpg)

.JPG)

y.jpg)

.JPG)

.JPG)

.jpg)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.jpg)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)