2013 turned out to be almost as productive as 2012. I managed to build a new resin kit of a

Jung locomotive. Mostly from the kit's parts but as usual I couldn't resist fitting some scratch built parts, a specially adapted figure and my first custom made etched works plates with the help of Mark Hesketh. One of my older locos was fitted with decoder and new O-rings and could take its place among the serviceable locos at Nystrup Gravel.

|

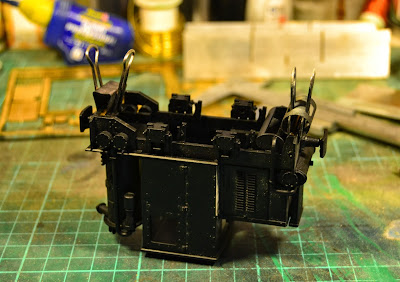

| The U-Models' Jung ZL 114 with etched works plates on the cab. The image serves as a reminder to me in Denmark that the cold and grey weather I suffer for the moment will give way to spring and summer in three month's time. |

I also managed to finish several road vehicles (and a huge off road crawler tractor). Among the road vehicles were Nystrup Gravel's director's

Opel Kapitän and haulage contractor Hansen's

Bedford O tipper.

|

| My research in the history of Nystrup Gravel also made progress in 2013. I found a complete binder with papers from the company and quite a few old pictures. Here is one of the company's director's Opel Kapitän about to cross the viaduct over the gravel line. |

In 2013 there seemed no end to the support from manufacturers for a modeller like me. A new etched brass O&K MD2 in 1:35 from

Hesketh Scale Models and steel sleepered track panels from

James Coldicott were very welcome. A surge of 3D-printed locos in 1:35 was suddenly made available on Shapeways. I bought my first and while the quality could be a little better, I was quite satisfied. And last but not least: What would be the release of the year (or the decade, dare I say!) is just about reaching the web shops: continental type skips in 1:35 in etched brass from the 1:35 industrial narrow gauge-alliance Hesketh & Snoodyk. I will now be able to exchange my old skips, first of all my Scale Link, some of which have served Nystrup Gravel since 1999. The Scale Link skips will not be scrapped but kept in reserve. I never throw out anything!

In October this little blog passed 30.000 page views. Just a fortnight later my collection of images on Flickr passed 100.000 view counts and November 2013 was the first month when Nystrup Gravel logged more than 3000 page views in a single month. I don't know if that is a lot in comparison with other related blogs, but I must admit being a little surprised that something so peripheral and downright weird as industrial narrow gauge modelling in 1:35 can attract that kind of interest.

As usual I have spent quite a few weekends at the 700 mm. gauge heritage railway

HVB and besides helping explain industrial railways to modern families and preserve history the work also gives great first hand knowledge of what works in reality. An important ingredient in modelling. A few trips abroad provided me with visits to narrow gauge railways.

|

| Surely the weather isn't always supportive of volunteering on HVB, but when the going gets tough, the tough gets going. Here the parasol I was holding to protect my friends from the rain has collapsed because of a sudden gust of wind. Working on a 1:1 railway surely is different from sitting at my modelling work bench. Photo: Finn Sørensen. |

Despite all other accomplishments at or near Nystrup Gravel, the emergence of a twin to Nystrup's speeder no. 7 surely counts as the year's most notable occurrence.

A 1:35 speeder built in Canada that exactly portrayed all features of my own little speeder really surprised me. I was incredibly honoured to see one of my models inspire a fellow modeller to build a model. I'm quite sure it was a once in a life time experience and I must look forward to other things in 2014. New skips, a running gas generator Schöma, a few road vehicles and perhaps the two bogie flats will enter service on my 1:35 version of Nystrup Gravel. The anniversaries of the battles of the Great War will probably lead to some modelling projects in the coming years. I don't expect to run out of inspiration.

Merry Christmas and Happy New Year!