With my intial diorama experiments in 1/87 having been quite satisfying I have been making minor additional investments in track and machinery in the scale. As I had to buy a length of track for the small circular diorama, I bought a variety of Code 55 points and track in 9 mm gauge for a future larger diorama in the scale. To accompany the Э-652б dragline excavator from Ukrainian K-Models I thought some underground mining equipment would look good next to a 750 mm siding. Fortunately a German company, Micro_Miners has taken up the production of mining equipment.

The models from Micro_Miners from Germany are a relatively new and highly detailed range of 3D printed models depicting equipment from the mining industry in DDR (East Germany). Even if the state fell apart and 'closed' in 1990 many of the machines produced in DDR for mining and industry were considered state of the art in the communist world. There is no denying that some of the designs looked decidedly 'cool'.

|

| Two mining vehicles on tires in 1/87 scale. Photo: Micro_Miners' web site. |

The following items were delivered swiftly and professionally packed:

12 'Stapelboxen/Lagercontainer'

The 'Wurfschaufellader' (overhead loader) in the box was quite a surprise as I hadn't ordered one! It may have been sent to Denmark by a mistake or simply as a generous gesture by Micro_Miners with the added benefit of filling the cardboard box completely?

|

| Good and sturdy cardboard boxes protects the small and delicate kits from hard handling. |

|

| A novel way of shipping fragile items. Hot glued to the bottom of the box avoids using huge amounts of plastic wrapping to protect the kits and the parts don't rattle about in the box. |

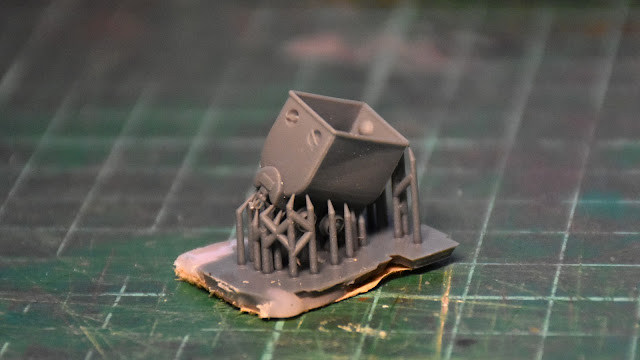

As the first image illustrates, the skip models are extremely small in comparison with my usual 1/19 scale models. A 1/87 0,63 m³ mine skip is only 1,5 cm long and 1,4 cm high with a width of 8 mm. To say that the models are tiny and fragile looking is an understatement!

My skips came 4 to a box. I have only separated one mine skip from the supports that carry the model during the 3D printing process. Separating the model from the supports seemed a daunting task, but with a little care and a sharp scalpel it worked out quite easy. The resin is surprisingly strong and I broke nothing on the little mine skip, despite my expectation of damage.

I'm not going to explore these little models more for the time being. The tiny skip will be wrapped in thin paper and packed away. The large scale model railway needs attention. Through my modelling I have learned that when nice models appear on the market it is wise to buy while one can. With small (sometimes enthusiast run) manufacturers the models may soon be impossible to source. Particularly 3D printed items that are often only printed on demand. My advise is: If you see something you like buy it (if you can afford it, of course).

|

| One mine skip ready for separating from the supports. |

|

| A rear view of a 1/87 mine skip showing the level of detail possible with modern 3D printers. |

%202.JPG)