One of the benefits of resin casting is the (relative) ease of production that enables manufacturers to model obscure prototypes. Very fine parts and prototypically thin edges can be made with resin. But most resins are brittle and not particularly well suited to the handling and mechanical stress that is unavoidable on a model railway. I think the Jung kit was designed for military modellers and most likely not intended for motorization. For a static model the resin is durable enough. As I will use the model to pull real trains I braced the frame of the locomotive with heavy plastic strip. It remains to be seen if the model will stand up to the ‘wear and tear’ of daily operation.

The kit parts makes it possible to build a 600 or a 700 mm . version of the loco. As Nystrup Gravel is using 600 mm . gauge the 700 mm . parts accompanied the kit buffers I mentioned in the previous Jung-post to the spares box. Two types of bonnet sides are also provided. I fitted the ones with the large Z-shape impressed into them. And yet more parts for the spares box!

|

| In this Jung fact sheet the ZL114 is fitted with side plates without the flashy 'Z'. I just couldn't miss the opportunity to have 'Z for Zorglub' on the side of a simple industrial locomotive. Readers of the Belgian comic 'Spirou et Fantasio' will know the villain Zorglub. |

|

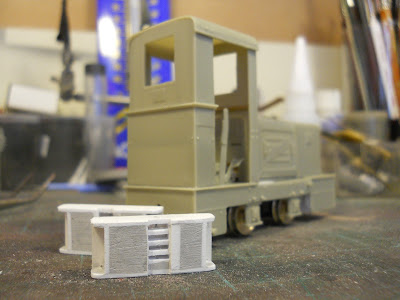

| Cab front fitted. I did work on yet another Scale Link skip while building the Jung. |

I added weight to the frame from scraps of brass. I struggled somewhat with a warped cab front, but managed to get it almost straight and glued in place. I will only glue the roof in place after having painted the interior of the cab. I decided not to fit the brake equipment as it would interfere with wires and easy handling of the Black Beetle. Sometimes you have to compromise.

|

| My renditions of the Jung cast metal buffers. They are built from plastic card and Humbrol putty. Next they will receive more sanding and a layer of primer before being sanded again. |