The first lengths of rails have finally been laid on the 16 mm scale Nystrup Gravel layout. It has taken far too long, but now the track is down and working, although it is only a very short length.

|

The first length of track spiked on the Nystrup Gravel layout.

|

The Peco Code 143 rail is 3,5 mm in height, corresponding to a ca 10-12 kg/m prototype rail. I have laid the sleepers with a scale 60 cm between centres. With 10-12 kg/m rail the track is fit for an axle loading of 2-2,5 tons with a good margin for heavier loads. It's not my intention to employ locos or wagons that will place much higher loadings on the track, though.

My track has been designed and reality checked with real industrial railway practice. I've used rail manufacturers' track manuals and the 'Industrial Railway 101' standard reference work 'Feldbahnen' by Paul Roloff, first published in 1950. The book is a practical guide for track foremen, contractors and planners helping them build, maintain and run narrow gauge industrial railways in an effecient and profitable way.

|

'Feldbahnen' written and compiled by Baumeister, Paul Roloff. A helpfull companion for any enterprising track foreman.

|

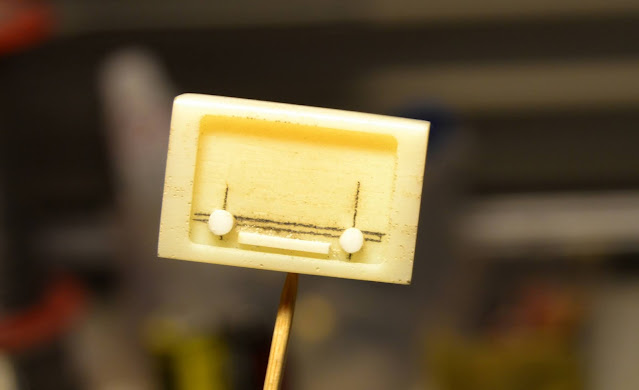

For track building I made three wooden track gauges reminiscent of the ones used on real narrow gauge industrial railways: a lenght of wood matching the gauge nailed to a piece of wood wider than the gauge to lay on top of the rail heads. Simple, easy to manufacture and fast when in use by the track workers.

|

Track gauge as illustrated in 'Feldbahnen'. A simple construction to keep the track in gauge during spiking.

|

|

My track gauges from wood and the gauge for keeping the right sleeper spacing.

|

|

Track gauges in use. The dress maker's pins keep the track in position during spiking.

|

The spacing between the sleepers is set by a 30 mm wide wooden block made from 3 pieces of old fireworks rocket sticks picked up after the new years celebrations. An easy and cheap supply of wood (as long as fireworks rockets are allowed). The sleepers are placed with the assistance of the guide block, their positions marked with a pencil, glue applied and the sleepers permanently fixed to the cork trackbed.

To avoid the rail ends at the module end being damaged during handling the module, I soldered the rail ends to brass screws firmly embedded into the module end. On my old 1:35 scale modules this method ensured easy alignment of track when setting up modules and a solid construction, keeping the track safe during transport, handling and setting up.

I will be using the Peco SM-32 Code 200 small radius turnouts I bought for test purposes. They will be rebuilt a little to fit into the Nystrup Gravel track and make them connect to the Code 143 rails.